- Animal oil production

- Commodity meat powder production

- Ingredients for pet food and feed

-

Concentrated soup

At present, we have deep cooperation with Alfa Laval, and use Alfa Laval's core technology and equipment to efficiently process slaughter by-products:

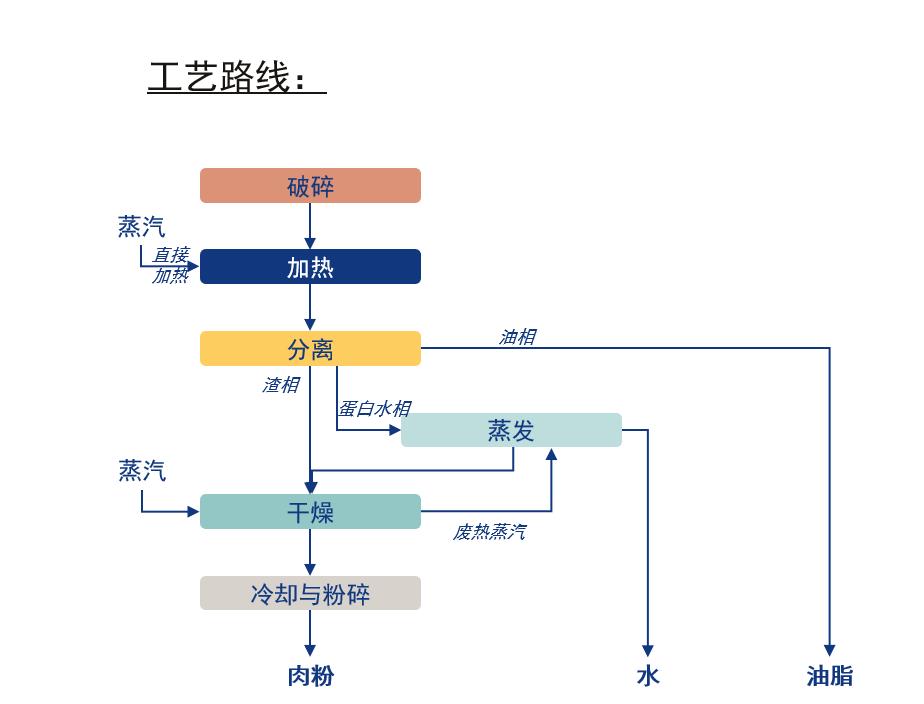

Such as illustration-process route:

- Firstly, the obtained by-products are fully crushed. On the one hand, breaking cells, tissues, structures, etc. can expose the products and facilitate extraction; On the other hand, crushing is beneficial to uniform heating, improving efficiency and reducing the possibility of "scorch"

- Heating the by-product. Alfa Laval uses high-temperature steam method to directly and rapidly heat the crushed by-products

- Use centrifuge to separate oil, protein water and solid meat residue

- Further separation and refining of oil

-

The protein wat will be evaporated, dry and purified

- Dry and pulverize the meat residue

- The content of meat powder, moisture, ash, crude protein and crude fat can be obtained as required

-

Features:

● Fully automatic control system;

● Feeding and discharging products for about 40 minutes;

● Technology of low temperature, heating and cooking for 1-3 minutes is suitable for raw materials with different compositions;

● Oil doesn't even need refining;

● Water and oil content of meat powder are controllable;

● Low energy consumption;

● It is closed, and the equipment is a food hygiene grade product without "paste smell".

-

Technological advantages:

● The VBN does not exceed the standard;

● Can adjust meat powder components according to requirements;

● According to the demand, "flavor" product groups can be produced, taking into account energy consumption;

● The material with high viscosity can be treated;

● When necessary, it can be disassembled and cleaned;

● Has high extraction and separation level, and can meet the harsh requirements of protein extraction industry;

● According to the requirements, special requirements such as product purification, clarification and concentration can be realized.

● Grinding machines, dryers and coolers can be purchased by customers according to their needs.

Compare with traditional production technology

-

Traditional dry method

● Unable to produce continuously;

● Production of meat powder has "paste flavor";

● Has simple process and less equipment;

● Very high energy consumption: 1.2 tons of steam/ton of raw materials;

● Oil has low purity and many impurities;

● Low water content, high oil content, low digestibility and carcinogenic risk of meat powder;

● Sanitary level is low, and cleaning is not fully considered in design;

● A big smell.

-

Traditional wet method

● The continuous production is possible, and the efficiency is high;● There is no burnt paste, and the digestibility of meat powder is high;● Lower energy consumption than traditional dry method;● Lower cooking efficiency and higher VBN;● Products have no "paste flavor";● The oil content of meat powder is still high due to the separation capacity of the press;● And can't treat protein water well.

-

Alfa laval wet process——CentriFlow

● Can be continuously produced with high efficiency;

● Basic non-oxidation of oil, high purity;● Water and oil content of meat powder are controllable;● Compare with conventional dry method, it can save more than 35% steam;● Take full account of cleaning, food hygiene level;● core centrifugal separation equipment and plate evaporation equipment have innovatively improved the separation level;● Products have no "paste flavor";● Compare with domestic equipment, the investment is higher.

Concept

With the increasingly stringent environmental protection requirements, the industrial concentration of the upstream, that is, the raw material end, has increased. But the change of residents' lifestyle, especially the younger generation, and the continuous urbanization have driven the increasing demand for animal fats and proteins.

At the consumer end, food and beverage consumption is growing strongly. Poultry meal is widely used in aquatic feed industry to replace some fish meal. In recent years, pet food industry, which is growing rapidly, also needs more high-quality meat meal. We believe that the processing of livestock and poultry by-products has a very good prospect.