May 20th, Guoxin No.1, the world's first 100,000-ton smart fishery large-scale aquaculture ship, was delivered and put into operation in Qingdao, and China's Shenyuanhai large-scale aquaculture ship industry achieved an advanced development from 0 to 1. Promote mariculture from offshore to deep sea and take the lead in the whole country.

The total length of the hull is 249.9 meters, with a displacement of 130,000 tons and a carrying capacity of 100,000 tons. The first "boat-borne cabin-rearing" mode is used to breed famous cultured fish species such as large yellow croaker, grouper and Atlantic salmon. By utilizing the world's high-quality seawater resources to breed, it provides China with high-quality marine protein, and becomes a new world of "mobile pasture" industrial breeding in China's sea.

As the supplier of the overall solution of the ship-borne processing system, Beyond Manufacturing Team provides a complete set of solutions for the processing line of large yellow croaker of this farming ship, realizing the production capacity of 100 tons/day of chilled large yellow croaker and 30 tons/day of frozen large yellow croaker.

Beyond Manufacturing Team, as the supplier of the overall solution of the ship-borne processing system, provides a complete set of solutions for the processing line of large yellow croaker of this farming ship, realizing the production capacity of 100 tons/day of chilled large yellow croaker and 30 tons/day of frozen large yellow croaker. We can also provide live fish carriers, processing mother ships, feed ships and supporting supply ships with BCM technical team. In the meantime, Beyond Manufacturing actively participates in the development and utilization of fish behavior monitoring technology and fry hatching equipment technology; We are committed to providing equipment, facilities and technical services for the integration of fishing, breeding and trade in marine fisheries.

Large yellow croaker caught from the breeding cabin can be processed into chilled fish or frozen fish according to the production situation after dormancy, transportation, pre-cooling and cooling. The fresh ice processing technology adopts the way of ice slurry precooling, cooling and keeping fresh, which can quickly put the fresh large yellow croaker to sleep, and quickly reduce the center temperature of the large yellow croaker to 0~-2℃, thus reducing the stress reaction of the large yellow croaker and effectively locking the golden color of the large yellow croaker's body surface. However, the storage at -1℃ makes the physiological state of the fish cells "freeze" at the moment of death, so the freshness of the fresh ice fish is similar to that of live fish. The frozen fish processing technology is the combination of ice slurry pre-cooling and quick-freezing tunnel quick-freezing, so that the central temperature of the fish is quickly reduced to -18℃ and then stored in cold chain. The quality of frozen fish is also better than that of the simple quick-freezing technology.

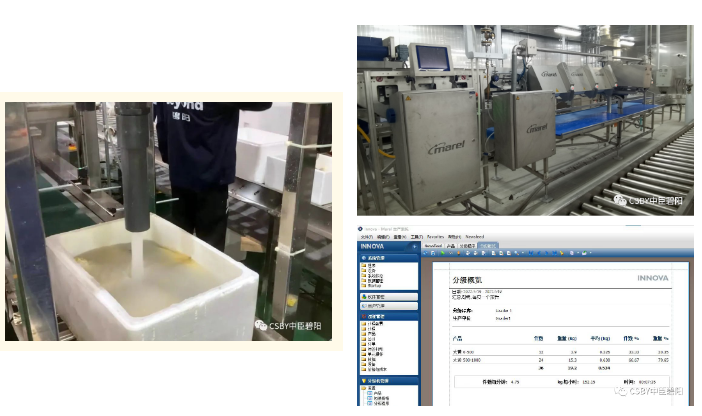

Fresh ice processing system improves the economic benefits of shipowners through the world's most professional Marel marine weighing and grading system and high-precision weight grading and packing. Meanwhile, by combining Innova production management software system, effective process control and real-time data can be provided for performance monitoring, which can support process improvement and improve work efficiency, thus helping shipowners to improve product quality and value.

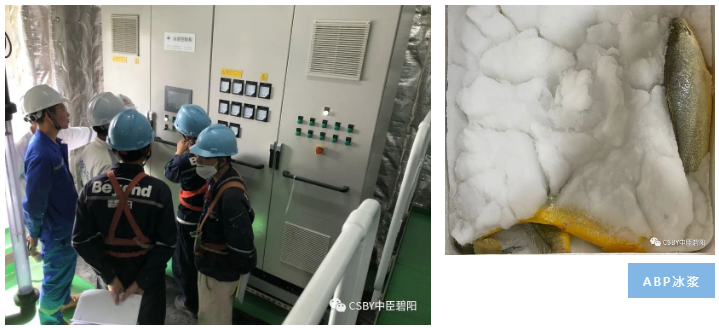

ABP ice slurry system is composed of several ice slurry units, which are installed in the equipment room in a modular way. Ice slurry with different concentrations is delivered to all processing links in the production line through delivery pumps and pipelines, and the caught large yellow croaker is precooled and packaged quickly, so as to ensure the high quality of large yellow croaker, and at the same time, the number of workers is greatly reduced and the processing efficiency is improved.

Ice slurry plays an indispensable role in the intelligent cultivation ship of large yellow croaker, and it can be seen in all links of the automatic production line. The newly caught large yellow croaker enters the dormant state after passing through the dormant pool of ice slurry, so as to avoid the stress reaction in the subsequent processing links. Then, these fresh large yellow croaker enter the precooling pool of ice slurry one after another through the conveyor belt, and the ice slurry melts and cools down, which quickly lowers the central temperature of the fish to freezing point. The extremely rapid cooling ensures that the large yellow croaker keeps a high-quality chilled state. After weighing and sorting, Pseudosciaena crocea coming out of the pre-cooling pool is packed and kept fresh according to different specifications, and the most important thing in this packing process is that it must be packed with high-concentration ice slurry. ABP ice slurry system realizes the regular and quantitative filling of high-concentration ice slurry, keeps the high-quality chilled state of Pseudosciaena crocea in the box, and prolongs the shelf life.

视频来源:蓝睛新闻

Contribution: Beyond Manufacturing Division

Proofread: General Management Department

Beyond Manufacturing is a team of Chonson Beyond, which focuses on aquaculture fishery services. Beyond Manufacturing provides: fishery processing solutions (including pre-processing, deep processing, hot and cold processing, etc.), fish collecting and catching solutions, automatic feeding solutions, etc. The whole life cycle management of fry from box entry to processing; In addition, we can provide the supply services of aquaculture auxiliary ships such as live fish carrier, processing mother ship, feed ship and supporting supply ship together with BCM technical team.